22

2023

-

05

2000 purpose price and market quotation of superfine pulverizer

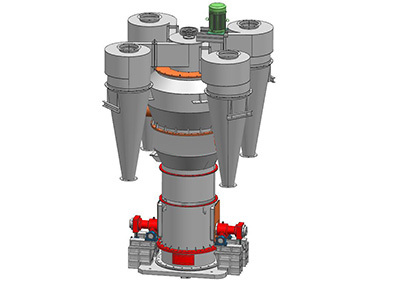

The price of the 2,000-mesh ultrafine grinding machine is about 200,000-600,000. Many users want to spend less money to buy good equipment, but after all, there are costs in the operation of every enterprise, and no one will make a loss-making business, so you get what you pay for, which still requires customers to buy Attention. Affected by factors such as different regions, manufacturers, market conditions, equipment models, etc., the overall quotation of Raymond Mill will fluctuate. If you want to get a more accurate equipment quotation, you can inquire about it. Raymond mill is widely used in the grinding processing of mineral materials in metallurgy, building materials, chemical industry, mining and other industries. It is suitable for the processing of various non-flammable and explosive materials with Mohs hardness lower than 7 and humidity lower than 6%. The fineness of the finished product is between 613μm and 44μm. Through the joint action of the analysis machine and the fan, it can meet the requirements of different users.

2000 purpose price and market quotation of superfine pulverizer

Commonly used models of pulverizers: Raymond mill

How to choose the correct model of Raymond mill

Analysis of Factors Affecting the Pulverization Effect of Ball Mill

2000 purpose price and market quotation of superfine pulverizer

The price of the 2,000-mesh ultrafine grinding machine is about 200,000-600,000. Many users want to spend less money to buy good equipment, but after all, there are costs in the operation of every enterprise, and no one will make a loss-making business, so you get what you pay for, which still requires customers to buy Attention. Affected by factors such as different regions, manufacturers, market conditions, equipment models, etc., the overall quotation of Raymond Mill will fluctuate. If you want to get a more accurate equipment quotation, you can inquire about it.

Raymond mill is widely used in the grinding processing of mineral materials in metallurgy, building materials, chemical industry, mining and other industries. It is suitable for the processing of various non-flammable and explosive materials with Mohs hardness lower than 7 and humidity lower than 6%. The fineness of the finished product is between 613μm and 44μm. Through the joint action of the analysis machine and the fan, it can meet the requirements of different users.

Commonly used models of pulverizers: Raymond mill

1. High product fineness

After being processed by the Raymond mill, the fineness of the finished powder is uniform;

2. High wear resistance

Important parts are made of high-quality steel, wear-resistant parts are made of high-performance wear-resistant materials, and the overall mechanical wear resistance is high

3. Good environmental protection

Change the disadvantages of the past mill design, change the bellows and air duct from the original horizontal bottom to 30 degrees to the center to ensure that the bellows and air duct are always unobstructed, and eliminate or reduce the pollution to the surrounding environment while collecting ultra-fine powder ;

4. Low investment cost

Compared with other milling equipment, Raymond mill integrates crushing, drying, milling and grading.

The transportation is integrated, the system is simple, the layout is compact, the floor area is about 50% of the ball mill system, and it can be arranged in the open air, which can greatly reduce the investment cost.

How to choose the correct model of Raymond mill

1. The hardness and particle size of the powdered material

When using Raymond mills to grind different ore materials, the selected equipment has different functional characteristics, sizes and models. If the raw material has high strength and large particle size distribution, corresponding crushing equipment must be equipped before grinding into powder to improve the working efficiency of Raymond mill.

2. Fineness requirements

Each user has different uses for the grinding stone, and the range of fineness required is also different. Therefore, in general, according to the requirements of different fineness, the requirements for the total number of rolls are also different. Therefore, people must communicate with the manufacturer about the grain size of the finished product when purchasing.

Grinding machine price

Analysis of Factors Affecting the Pulverization Effect of Ball Mill

①Influence of the structure of the lining plate Generally used in ball mills in industrial production, the product particle size is mostly 100~325 mesh. In the structural design of this kind of pulverizer, the ball milling medium is mainly required to effectively impact and crush the material, and the lining of the cylinder wall is mostly non-smooth (such as trapezoidal, convex, k-shaped, etc.). ), this structure enables the barrel of the ball mill to effectively input the rotational energy into the ball milling medium, but at the same time it also leads to a great reduction in the falling state of the ball milling medium, and the grinding effect of the grinding medium on the material is greatly reduced. Undoubtedly, this situation is not conducive to the ultrafine pulverization of materials. If the ball mill requires effective ultra-fine crushing of materials, the grinding effect of the grinding medium should be strengthened, and the inner wall of the cylinder should be as smooth as possible.

②The influence of the speed is within a certain range. When the speed of the ball mill increases, the grinding of the material comes not only from the grinding, impact and grinding of the balls, but also from the grinding and crushing caused by the relative motion between the outermost ball and the cylinder wall and the balls of each layer. , to a certain extent, the production capacity and output of the ball mill can be improved, but the wear of the liner and the specific energy consumption increase, especially in order to increase the working speed of the ball mill, it is necessary to reduce the loading of the balls, reduce the loading of the balls, and reduce the production capacity and output

③Influence of the filling rate of the grinding medium The filling rate of the grinding medium is improved. In the case of the same cylinder volume, the amount of balls loaded and the number of effective grinding balls for crushing are increased, and the production capacity and output can be improved under certain conditions. However, the filling rate of the grinding media should not be too high. Generally, the larger the diameter of the cylinder, the lower the filling rate of the grinding media, the higher the filling rate of the grinding media, the higher the accumulation of the grinding balls at the drop point of the grinding balls, the slower the impact of the grinding balls, and the higher the output and crushing efficiency The lower the value, the higher the energy consumption.

In the wet ball mill, the filling rate of the grinding medium is about 40%, and more than 40% is a high filling rate, on the contrary it is a low filling rate. The filling rate of the grid type ball mill is 40%~45%, mostly about 45%, and the filling rate of the overflow type ball mill is 40%. It should also be pointed out that when the filling rate is 55%, the output and power consumption of the ball mill are the largest, but it is also higher than the energy consumption. During dry grinding, the grinding material between the grinding media will expand the grinding media, so that the material is hindered by the grinding media, and the axial fluidity is poor, so the filling rate of the grinding media should not be too high.

④Influence of the proportion of grinding ball diameter The size of the grinding medium and the inner cavity of the cylinder has a significant impact on the crushing effect of the ball mill, especially the proportion of grinding balls of different sizes in the cylinder in the ball mill, because the combination of grinding balls of appropriate size is beneficial Increase the crushing effect area, thereby improving the ultra-fine crushing effect.

The ratio of the diameter of the grinding balls is generally based on the feed particle size and empirical data to select several diameters of grinding balls, so that the total area of each diameter of the grinding balls is equal. Thus, the percentage of each grinding ball to all grinding ball loads can be calculated, and the weight percentage of grinding balls of various diameters is generally proportional to the diameter of the grinding balls.

⑤Influence of dry and wet crushing methods Dry crushing operation is relatively simple, but the particle size of the product is often coarse, and the finest product in large-scale industrial production generally can only reach about d=5um. The operation of wet pulverization is complicated, but it can produce products with fine particle size, and industrial production generally reaches products below d6=3um.

Related News

Guilin Guiqiang Machinery Co.

Address:No.2, Pailou New District, Lingchuan, Guilin

Mobile Number : +8613517860005 Mr. Tian

Landline:+86-0773-6819921

E-mail:3369423711@qq.com

Public

Mobile Station