22

2023

-

05

Raymond Mill Automatic Feeding | Raymond Mill and Dust Collector

Raymond Crusher, referred to as Raymond Crusher, is a commonly used crushing equipment. Raymond grinder originated abroad. At present, the development, research and production of Raymond mills (Raymond mills) in my country have matured. Raymond pulverizer has the characteristics of high efficiency, low power consumption, small footprint and less one-time investment. Raymond mill can effectively grind ore, suitable for marble, talc, potassium feldspar, calcite, barite, etc., and can also be used for grinding gypsum, activated carbon, bentonite, kaolin, cement, glass, insulation materials, etc. 280 kinds of materials in non-flammable and explosive construction, mining, chemical and other industries with a hardness of no more than 9.3 and a humidity of no more than 6%.

Introduction to Raymond Crusher

performance advantage

price advantage

working principle

Raymond Mill Structure

Technical Parameters

Introduction to Raymond Crusher

Raymond Crusher, referred to as Raymond Crusher, is a commonly used crushing equipment. Raymond grinder originated abroad. At present, the development, research and production of Raymond mills (Raymond mills) in my country have matured. Raymond pulverizer has the characteristics of high efficiency, low power consumption, small footprint and less one-time investment.

Raymond mill can effectively grind ore, suitable for marble, talc, potassium feldspar, calcite, barite, etc., and can also be used for grinding gypsum, activated carbon, bentonite, kaolin, cement, glass, insulation materials, etc. 280 kinds of materials in non-flammable and explosive construction, mining, chemical and other industries with a hardness of no more than 9.3 and a humidity of no more than 6%.

Raymond mill: fineness controllable, high screening rate.

On-site training guides technical personnel to ensure post-production.

performance advantage

1. It adopts vertical structure design, occupies a small area, and has a strong complete set. It can establish an independent production system in terms of rough processing of raw materials, transportation, milling, and packaging.

2. Compared with other mills, the sieving rate is high, up to 99%, which is difficult for other mills. With the centralized control of the electrical system, the Raymond mill grinding workshop can basically realize unmanned operation and improve the working environment.

3. The manufacturer has not only improved the traditional feeding method, but also improved the main shaft and plum blossom frame, which is conducive to stable structural transformation, making its transmission stable and reliable in operation.

4. The main parts of the equipment are casted with high-quality materials, and the craftsmanship is fine, which ensures that the overall operating efficiency of the Raymond Mill equipment is high and the wear resistance is good.

Spot supply, timely delivery, no delay in construction period.

price advantage

How much is the price of Raymond grinder? This is a concern of consumers, but due to different manufacturers, equipment production technology, manufacturing principles, etc., manufacturers have different overall estimates of equipment. Red Star manufacturers provide many consumers with high-quality Raymond pulverizers and high crushing efficiency. , users can customize the equipment according to the actual production situation. Redstar has a superior geographical location and direct sales. The price of the Raymond crusher and other crushing equipment produced by Hongxing is relatively cheap. If you want to know the more detailed price of the equipment, please consult online. We have someone evaluate the equipment you need.

Technology + dedication = high-quality equipment, please rest assured to buy.

High-efficiency work efficiency can ensure continuous and efficient work of users and create greater economic and social benefits for users

1. Pre-sales: special car to pick up and drop off the users who come to the factory, provide free trial operation, and provide free production process plan;

2. Sales: Available from stock, more timely delivery. At the same time, users can install and debug the purchased equipment, provide technical guidance and training to the company's operators for free, and provide guarantee for the normal and efficient operation of the equipment.

3. After-sales: Provide accessories, deal with customer feedback problems in a timely manner, reduce equipment downtime, reduce customer investment costs, and create higher economic and social profits for customers in the later period.

Private car pick-up, don't worry about the limited number.

Accompanied throughout the process, answering questions one-on-one on the spot.

working principle

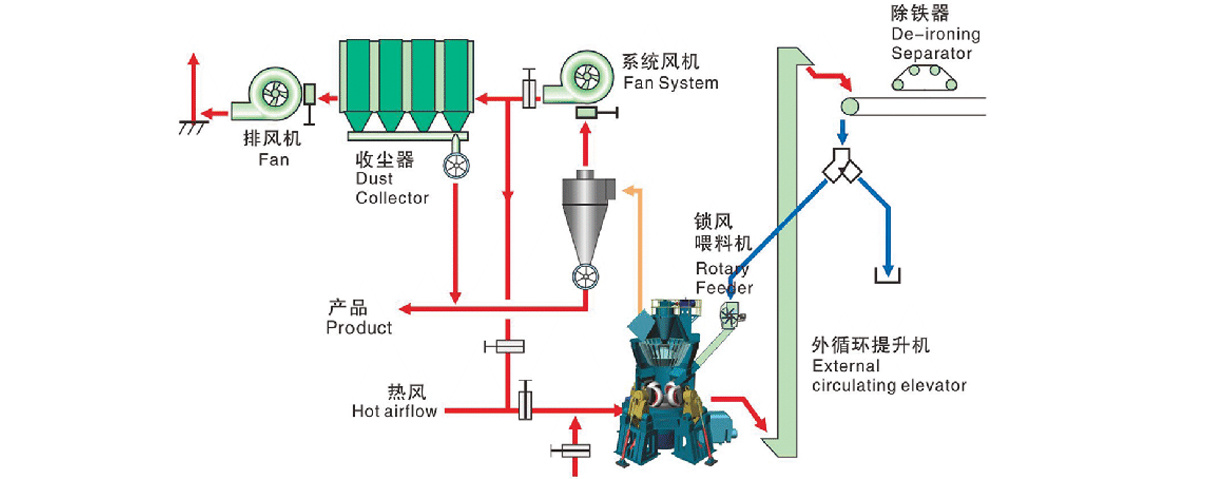

When working, put the material to be crushed into the machine from the hopper on the side of the casing, and rely on the grinding roller device suspended on the plum blossom frame of the body, while rotating on the vertical axis, it will rotate by itself, due to the centrifugal force during rotation , the grinding roller of the Raymond mill swings outwards and presses on the grinding ring, and the shovel sends the material between the grinding roller and the grinding ring

After the Raymond grinder (Raymond grinder) grinds the material, the fan blows the wind into the main casing, blows up the powder, and sorts through the analyzer placed above the grinding chamber, and the material that is too fine falls into the grinding chamber. chamber for re-grinding, and the fineness meets the specifications of the wind flow into the cyclone collector, after being collected, it is discharged through the powder outlet, and the finished product is finished. The air flow is returned to the fan by the return air pipe at the upper end of the large cyclone collector, and the air path circulates and flows under negative pressure. The increased air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine, and enters the small cyclone collector for purification treatment .

Raymond Mill Structure

The structure of the machine is mainly composed of main engine, analysis machine, blower, finished product cyclone separator, pipeline device, motor and so on. Among them, the main engine is composed of a frame, an intake volute, a shovel, a grinding roller, a grinding ring, a casing and a motor. Raymond mill and jaw crusher, bucket elevator, electromagnetic vibrating feeder, electrical control cabinet, etc. It can be used in gypsum powder processing, coal powder preparation, power plant desulfurization, etc.

Raymond mill is mainly composed of main shaft, grinding ring, grinding roller and grinding roller.

Motors, V-belts, blades and other structures.

Technical Parameters

Model parameter 4525419.

Feeding particle size (mm)≤30≤25.

Finished particle size (mm) 0.173-0.0440.173-0.044.

The fineness of each material shift production (t) 16-1768-78.

Central shaft speed (r/min) 82105.

The grinding ring diameter is 17701400.

Roll diameter (mm) 450410.

Grinding roller height (mm) 250190.

Main motor Y315M-4-132Y280S-4-75.

Fan motor Y315M-4-132Y280S-4-75

Analysis motor YCT250-4A-18.5YCT200-4B-7.5

Related News

Guilin Guiqiang Machinery Co.

Address:No.2, Pailou New District, Lingchuan, Guilin

Mobile Number : +8613517860005 Mr. Tian

Landline:+86-0773-6819921

E-mail:3369423711@qq.com

Public

Mobile Station