22

2023

-

05

What are the laboratory ore pulverizers?

Ore mills for laboratories include sand and powder integrated machines-GQ series/GQZ small ultra-fine powder Raymond mills and other small mills.

What are the laboratory ore pulverizers?

Sand powder machine-GQ series

GQZ small ultrafine powder Raymond mill

What are the laboratory ore pulverizers?

Ore mills for laboratories include sand and powder integrated machines-GQ series/GQZ small ultra-fine powder Raymond mills and other small mills.

Sand powder machine-GQ series

What is a sand making machine

The new sand making machine (vertical shaft impact crusher) is suitable for crushing soft or medium hard and extremely hard ore materials with a hardness not higher than 320Pa. Sand making machines are widely used in large, smelting, building materials, roads, railways, water conservancy and Chemical industry and many other sectors.

Features

1. Simple structure and low cost.

2. High efficiency and energy saving, high crushing efficiency.

3. It has the functions of fine crushing and coarse grinding.

4. Strong ability to pass non-broken materials, less affected by material moisture, moisture content can reach 8%.

5. It can crush medium-hard and extra-hard materials (such as corundum, sintered bauxite, etc.).

Sand powder all-in-one machine

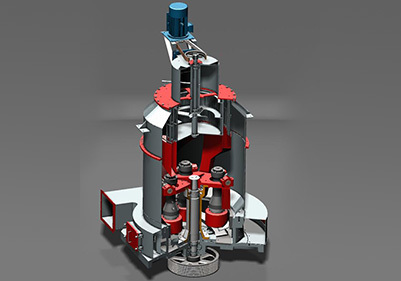

GQ series sand making machine is also called impact sand making machine, direct impact sand making machine and impact crusher. It has achieved excellent market share in the national market. The product performance is more perfect. It is an ideal production equipment for sand and gravel materials, cushion materials, asphalt concrete and cement concrete aggregates.

Application field

In the field of mining, it is widely used in the front-end process of grinding, which can produce a large amount of fine ore and reduce the high-cost grinding load. In addition, the GQ series sand making machine can be well used in the production of glass, quartz sand and other high-hardness materials, coupled with zero pollution to the product, the production capacity range of 10-500t/h can meet almost any production Require. It has won the trust of customers and won the favor of customers at home and abroad.

GQZ small ultrafine powder Raymond mill

Break through the bottleneck of fine powder processing and fill the gap in the small ultrafine Raymond mill market-patented product

GQZ small ultra-fine powder Raymond mill can reduce the empty grinding phenomenon of the main machine, reduce vibration, improve the grinding efficiency, and this technology greatly improves the fineness of the ground powder. The particle size of the finished product can reach more than 400 mesh. The traditional pulverizer will regrind the powder that is too fine (that is, the powder that fails to pass through the analyzer) and falls freely into the main machine. During the free fall process, a large part of the material cannot fall to the grinding ring and the grinding ring under the influence of wind. The grinding rollers are re-grinded and suspended between the main machine and the analyzer, so when grinding fine powder above 400 mesh, the machine has serious empty grinding phenomenon, large vibration and low output. The electric energy is wasted, the mechanical loss is increased, and the whiteness of the powder is reduced, so that the Raymond machine has no advantage when grinding the powder above 400 mesh.

1. Improve the whiteness of the ground powder

It solves the problem that a large part of the powder cannot fall between the grinding ring and the grinding roller under the influence of the wind force during the free falling process, and is suspended between the main machine and the analysis machine, resulting in the fineness of more than 400 mesh. The phenomenon of machine empty grinding when powdering. The vibration is small and the output is high, which improves the whiteness of the ground powder.

2. The fineness can reach 400--800 mesh

The deflector and the feeding hopper are added, so that the powder that has just been ground from the main machine and has not been sorted is led by the airflow to the inner wall of the mill and passes through the deflector evenly. The deflector also prevents the analyzer from sorting out Powder that is too coarse cannot return to the upward airflow, and falls down to the coarse powder receiving bucket along the inner wall of the deflector, and is sent into the gap between the grinding roller and the grinding ring by the lower part of the coarse powder receiving bucket for regrinding, ensuring that the grinding ring There is sufficient material between the machine and the grinding roller at any time, so the empty grinding phenomenon of the main machine is solved, the vibration is reduced, and the grinding efficiency is improved, so the fineness of the ground powder is greatly improved.

3. Fast energy saving

It solves the empty grinding phenomenon of the main machine, reduces vibration, improves grinding efficiency and reduces energy consumption.

Related News

Guilin Guiqiang Machinery Co.

Address:No.2, Pailou New District, Lingchuan, Guilin

Mobile Number : +8613517860005 Mr. Tian

Landline:+86-0773-6819921

E-mail:3369423711@qq.com

Public

Mobile Station